Induction Hardening

High-Frequency Generator

The energy-conserving, all-solid-state type high-frequency generator delivers high-efficiency and stability in a compact package, and is the choice of many customers. The standard model supports frequencies from 20 kHz to 200 kHz, and outputs of 1 kW to 200 kW.

Advantage

feature1Surfaces can be hardened in a very short time of period.

feature2Hardened depth is adjustable.

feature3Heating of limited areas is possible.

feature4Uniform, high-quality hardening is obtained.

feature5Hardening achieved at very low cost.

feature6Workpiece materials may be changed from high priced alloy steel to inexpensive carbon steel.

Applications

- Continuous annealing, such as pipe, electrical wire, steel wire, etc.

- Heating power supply for MOCVD, vapor deposition CVD, magnetic levitation

- Various processing, including hardening, brazing, dissolution, etc.

- SiC (crystal, CVD, annealing)

Characteristic

- Compact design: Volume ratio 61% Footprint ratio 71% (Internal comparison for output 200kW)

- Supports a wide frequency range: 1kHz to 400kHz

- Supports a wide output band: 10kW to 200kW

- High reverse conversion efficiency: 90% to 95%

Options

- Heating coil

- Mechanical system

- Output switch unit (automatic / manual)

- Frequency switch unit (automatic/ manual)

JMT transistor inverter series standard specifications

| Model | Output power [kW] | Frequency [kHz] | Input voltage [V] | DC voltage [V] | DC current [A] |

|---|---|---|---|---|---|

| JMT-15 | 15 | 1~400 | 3φ、220 | 260 | 65 |

| JMT-30 | 30 | 1~400 | 3φ、220 | 260 | 130 |

| JMT-50 | 50 | 1~400 | 3φ、220 | 260 | 220 |

| JMT-100 | 100 | 1~400 | 3φ、440 | 520 | 210 |

| JMT-150 | 150 | 1~400 | 3φ、440 | 520 | 310 |

| Model | DC output [kW] | AC input [kVA] | Weight [kg] | Cooling water [L/min] | Unit dimensions [mm](W×D×H) |

|---|---|---|---|---|---|

| JMT-15 | 16.9 | 20 | 165 | 10 | 600×450×1200 |

| JMT-30 | 33.8 | 40 | 180 | 20 | 600×450×1200 |

| JMT-50 | 57.2 | 65 | 195 | 20 | 600×450×1200 |

| JMT-100 | 109.2 | 130 | 660 | 45 | 1000×955×1750 |

| JMT-150 | 161.2 | 195 | 680 | 60 | 1000×955×1750 |

※Specification may be revised without notice as improvements are made.

HF Generator

H-100D HF Generator

[100kw output,10/100kHz switchable]

Induction heating using RF current is now widely utilized in industries for applications such as hardening/tempering/annealing of steel, forging, melting, brazing, etc. There are several types, including the vacuum tube type, transistor type and thyristor type, which are selected for the application according to their different characteristics.

Based on more than 50 years of experience and unrivalled expertise, NDK can meet any customer requirements in this area.

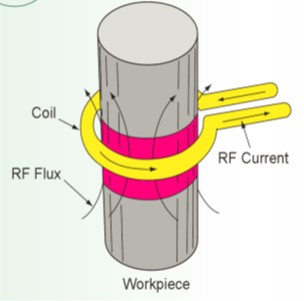

Principle

When the metallic workpiece is placed in a coil, an RF current is applied to the coil, and RF current is induced on the surface of the workpiece causing it to heat up. The heated portion is quenched by using coolant such as water to harden.

High frequency generator standard specifications

| Spec\Model | JMT-series Transistor inverter type | JHS-series Conventional Vacuum tube type |

|---|---|---|

| Input power [V(three phases)‐kVA] |

200-440・20-260 | 200-440・10-450 |

| Frequency range [kHz] |

1~400 | 20~400 |

| Nominal output power [kW] |

15~200 | 5~200 |

| Cooling water [L/min] |

60~150 | 22~300 |

※Specification may be revised without notice as improvements are made.

Hardening Machines

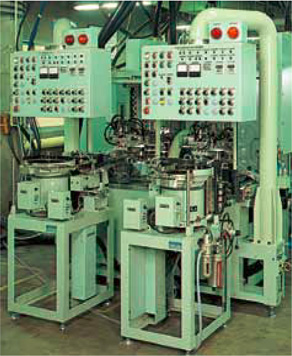

N-2QM series hardening machines are designed for hardening of small size gears, cam shafts and rod type products. The N2-QM model transfer distance is standardized to 600, 900, and 1200 mm.

Special purpose or automated machines are available upon request.

N-2QM series hardening machine with integrated control and operation board(PSW programmer)

Automated hardening machine for small parts

Vertical type computer-controlled hardening machine

![Bed type hardening machine 2 m [W] × 4 m [L], 4 m-stroke](/img/img_heating06.jpg)

Bed type hardening machine

2 m [W] × 4 m [L], 4 m-stroke

Automated hardening machine in nitrogen atmosphere

Automated horizontal type hardening machine for shafts

Robot in operation and vertical type hardening machine

Water Cooling Unit

This is a water cooling unit to control the cooling water temperature for the HF generator and coolant.